The laboratory is equipped with testing systems capable of performing

- Tensile tests for temperature up to 1150°C.

- Low & High–Cycle Fatigue tests in air and in vacuum for temperatures up to 1150°C.

- Thermo-Mechanical Fatigue tests in air and in vacuum for temperatures up to 1150°C.

- Creep & Stress Relaxation tests for temperatures up to 1150°C.

Testing is generally conducted on specimens according to international standards.

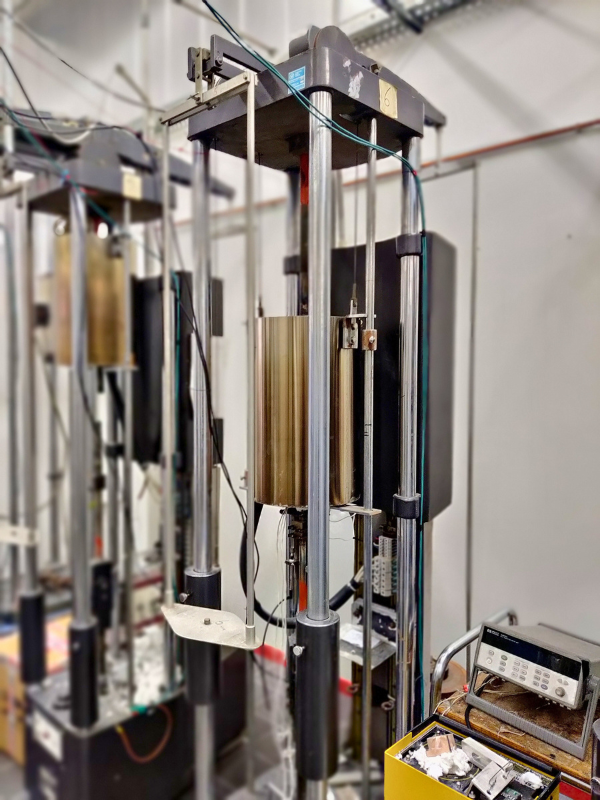

Creep testing machine equipped with a tubular oven for testing up to temperatures of 1100°C.

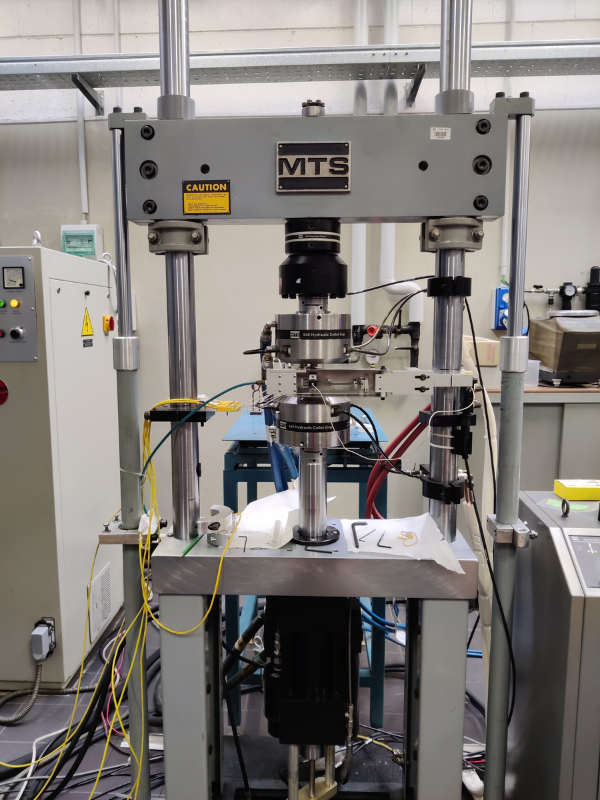

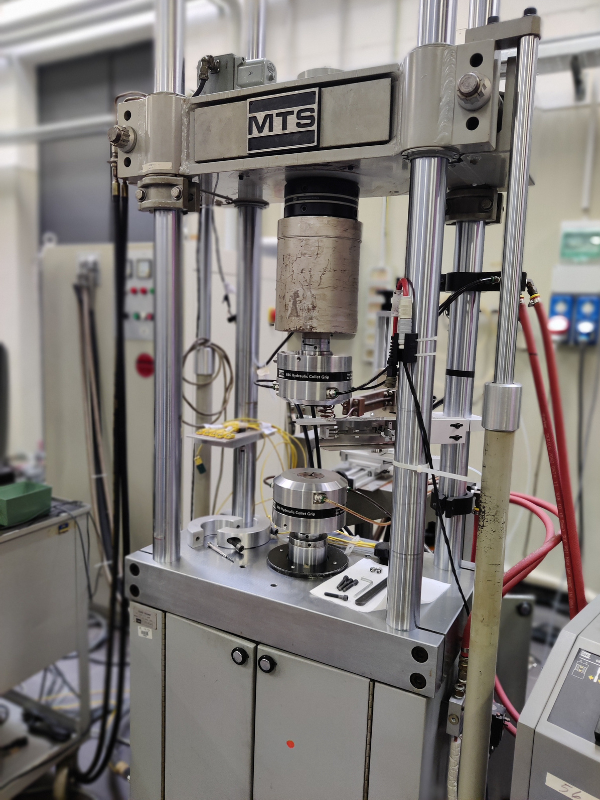

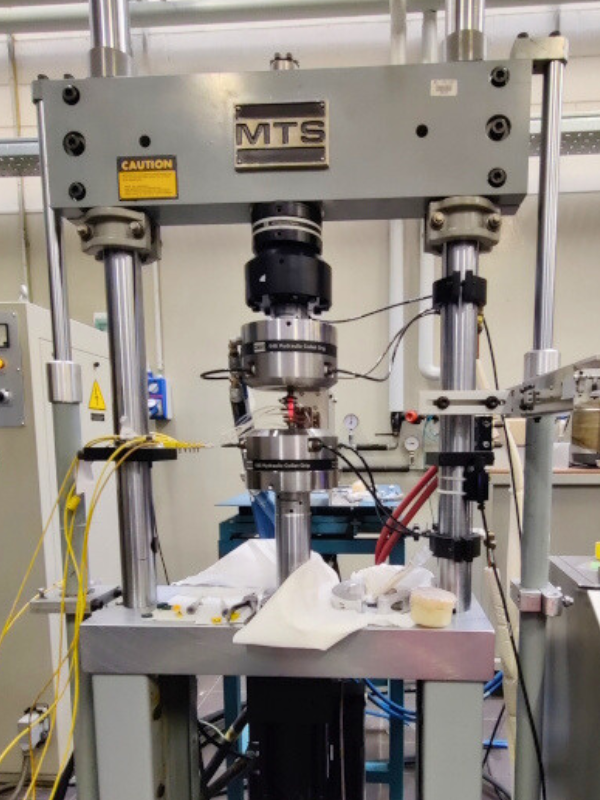

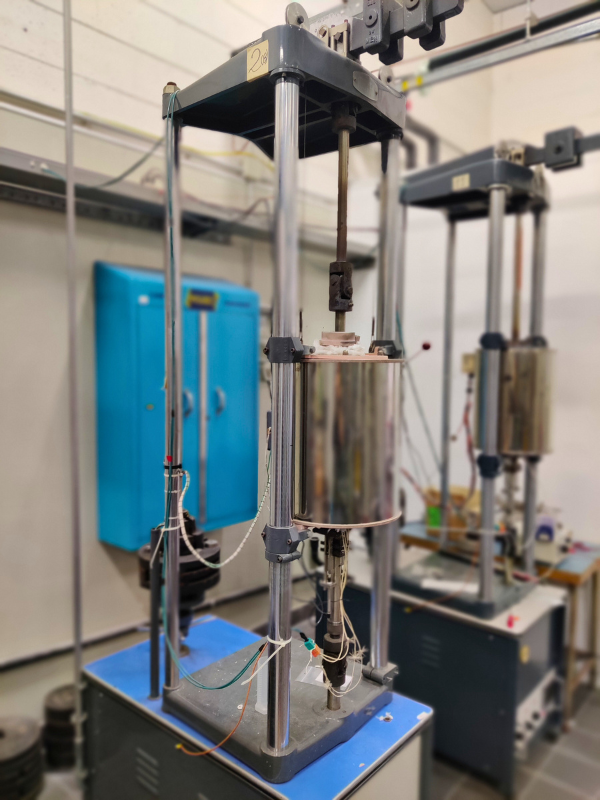

MTS 100kN LCF and TMF testing machine during a test

EQUIPMENT

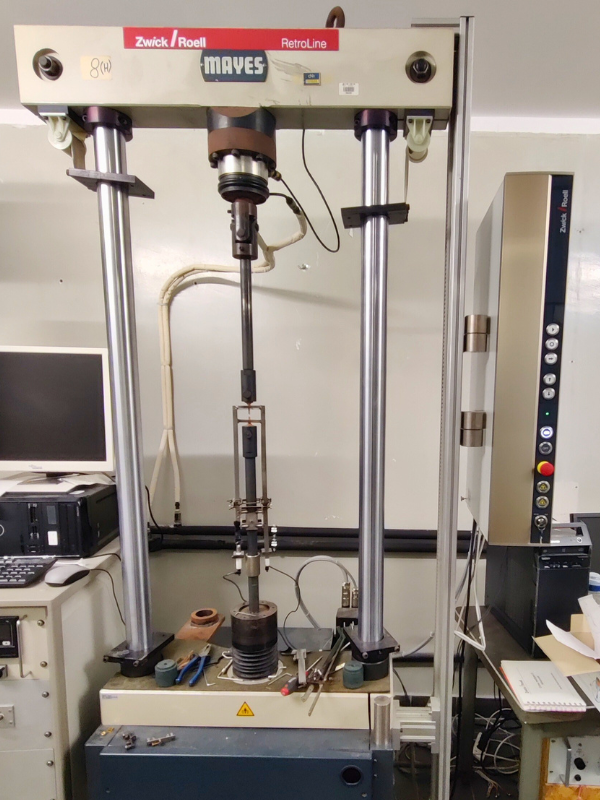

- Two servo-hydraulic testing machines up to 200 kN and 100 kN for low-cycle fatigue tests and thermomechanical fatigue tests in air up to 1150°C (induction heating system);

- One servo-hydraulic testing machine up to 100 kN for low-cycle fatigue tests in air up to 1000°C;

- Two electromechanical testing machines up to 50 kN for tensile, creep and stress relaxation tests in air up to 1150°C;

- Fifteen creep testing machines working up to 30 kN and 1150°C;

- Two machines for rotating bending fatigue tests;

- Durometer for Vickers, Rockwell and Brinell hardness tests;

- Two muffle furnaces for heat treating up to 1200°C.

- Furnace Naberterm Top 45, Tmax 1300 °C

- Setup for high temperature microthermocouples (25-120 micron) preparation

Samples of different shapes and sizes can be tested in the laboratory.

Stainles steel tensile specimens tested at different temperatures.

Alloys of interest to industry are tested, such as

- Nickel based superalloys (either polycrystalline or single crystal)

- Intermetallics (TiAl)

- Titanium alloys

- Oxide-dispersion-strengthened alloys (ODS)

- Low & High-alloyed steels

- Stainless steels

- Iron Cast alloys as ADI (Austempered Ductile Iron)

- Copper alloys.

Tests on pure metals, such as copper or nickel, are performed for research purposes.

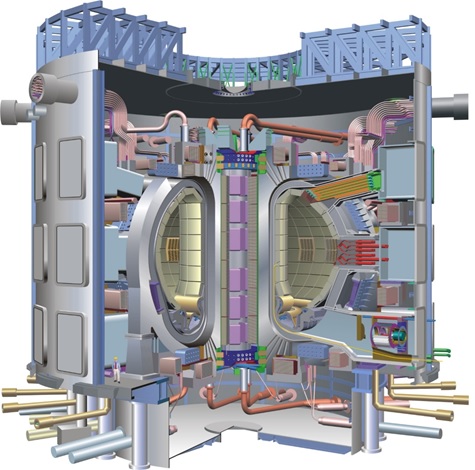

Materials of industrial interest are used in the energy sector, particularly for land and aircraft gas turbines or Nuclear fission and fusion power plants, in heavy transport and in advanced manufacturing.

The laboratory is strongly committed to the tasks of the the European Consortium for the Development of Fusion Energy EUROfusion.

A small focus on Fatigue testing

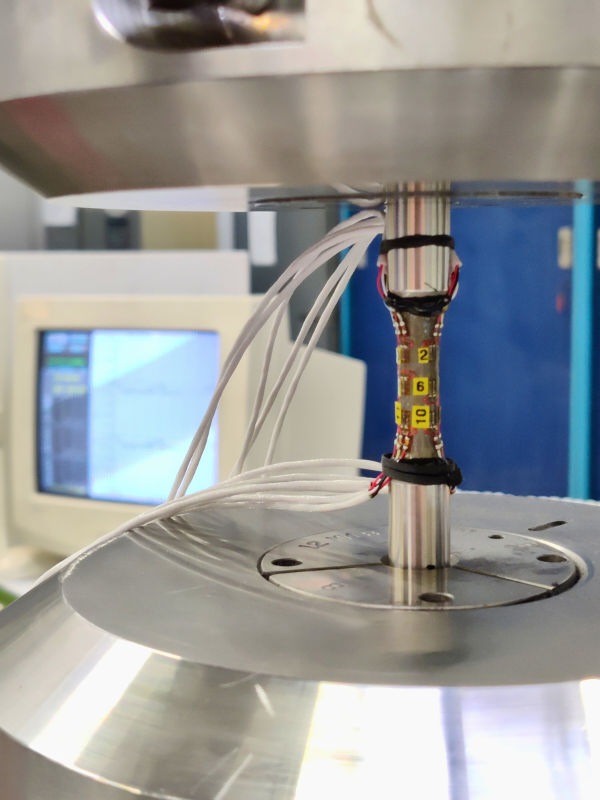

LCF and TMF test machine load line alignment procedure using a strain gauge specimen

Welding of type K thermocouples to the sample surface

Calibration test specimen for LCF fatigue tests, equipped with No. 5 K-type thermocouples welded on the surface (No. 3 in the useful section and No. 2 at the top and bottom of the specimen)

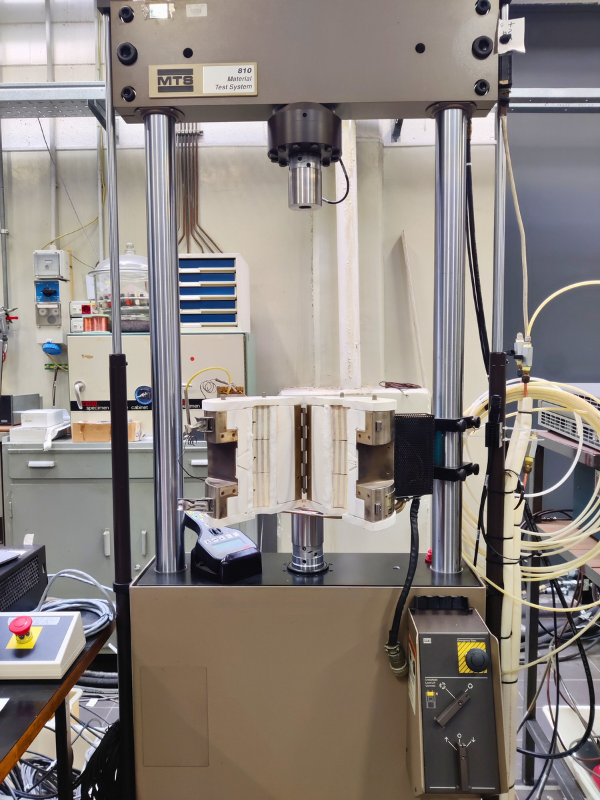

The laboratory is equipped with two servohydraulic MTS machines for oligocyclic fatigue and thermo-mechanical tests with induction heating for temperature up to 1150°C in air: specifically, a 100kN machine and a 200kN machine.

In addition to these, there is a 100kN MTS machine with furnace heating for oligocyclic fatigue tests for temperature up to 1000°C.

A small focus on Creep testing

Creep sample mounted on the test machine.

Detail of strain gauge bevels attached to the specimen surface

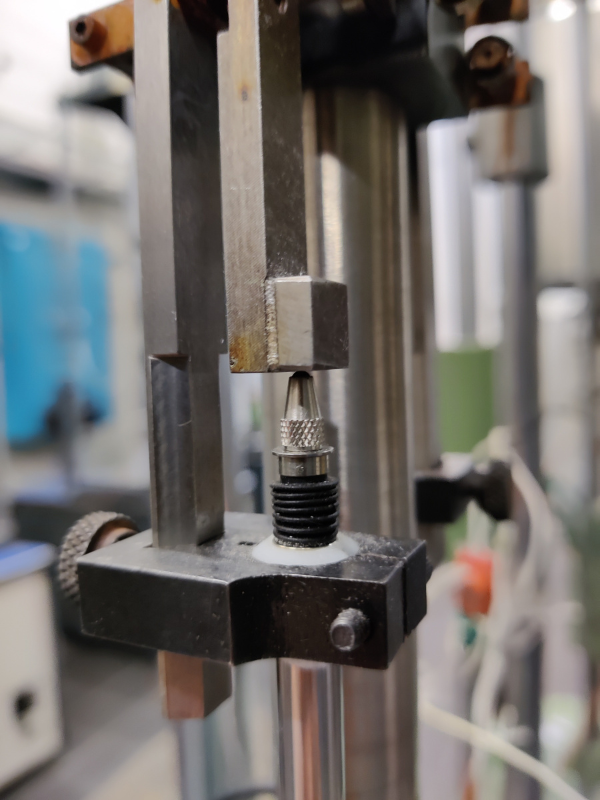

Detail of the capacitive transducer used to measure the deformation of the sample during the test.

The Laboratory is equipped with a total of 15 machines for creep tests. In particular, there are

- 5 machines with double lever ratio 4X + 40X

- 4 machines with 15X lever ratio

- 3 machines with 40X lever ratio

- 2 machines with 20X lever ratio

In addition to these there are 2 electromechanical machines for tensile, creep and stress relaxation tests up to temperatures of 1150°C.

Other instrumentation in our laboratory

There are also other instruments as:

- Two machines for rotating bending fatigue tests

- Durometer for Vickers, Rockwell and Brinell hardness tests

- Two muffle furnaces for heat treating up to 1200°C.

- Furnace Naberterm Top 45, Tmax 1300 °C

- Setup for high temperature microthermocouples

(25-120 micron) preparation

Durometer for Vickers, Rockwell and Brinell hardness tests

One of the two ITALSIGMA machines for rotating bending fatigue tests.