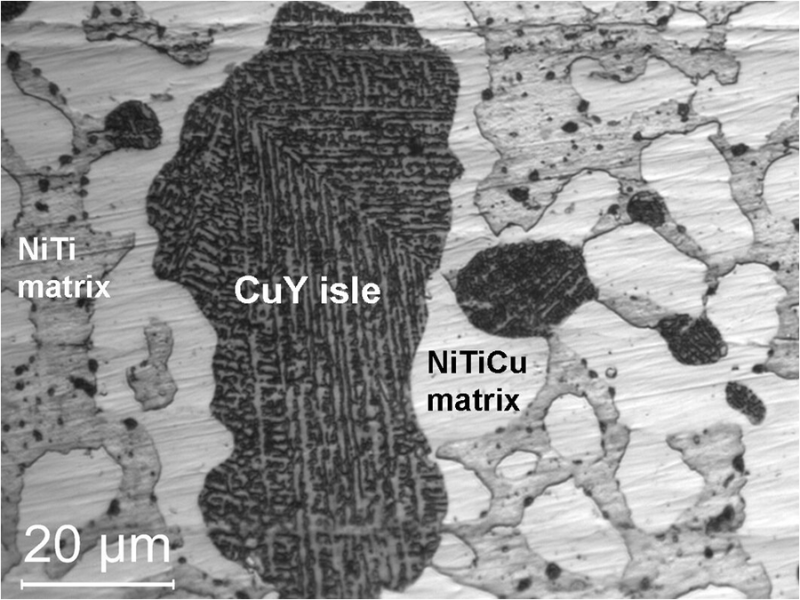

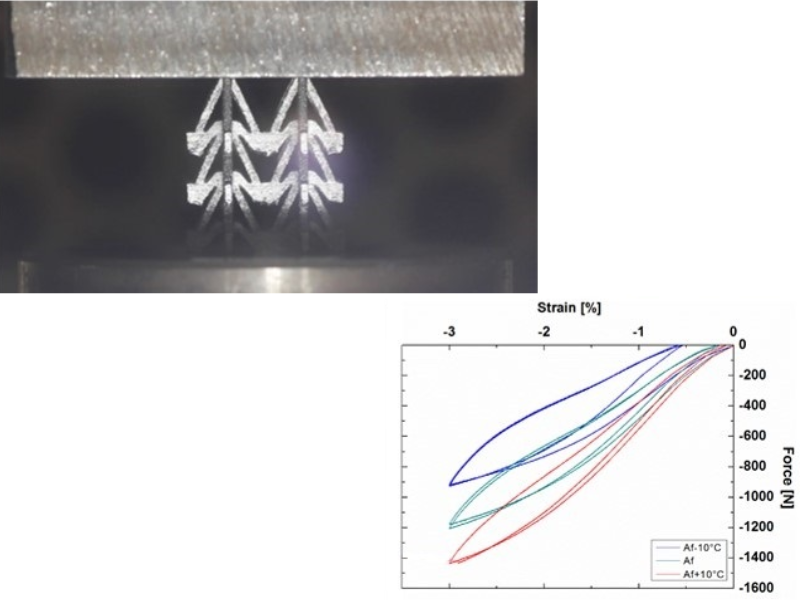

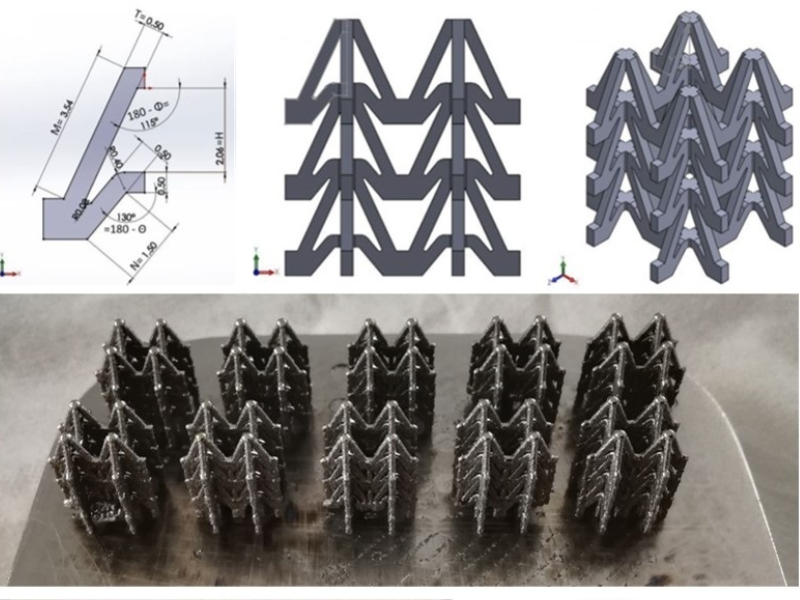

The intersection of additive manufacturing (AM) and shape memory alloys (SMAs) presents exciting opportunities for advancing energy conversion technologies. The ability to design and produce complex, tailored SMA components opens new avenues for improving efficiency and performance in various energy-related applications. ICMATE is active in research activities involving the development and optimization of SMA materials suitable for additive manufacturing processes. These include fine-tuning the composition and processing parameters to ensure that the printed SMA components exhibit the desired shape memory effects and mechanical properties.

The exploration of various additive manufacturing techniques tailored for SMAs, such as direct energy deposition, selective laser melting, or other powder-bed fusion processes are active research areas. The goal is to achieve high-quality, functional components with precise control over their microstructure and properties.

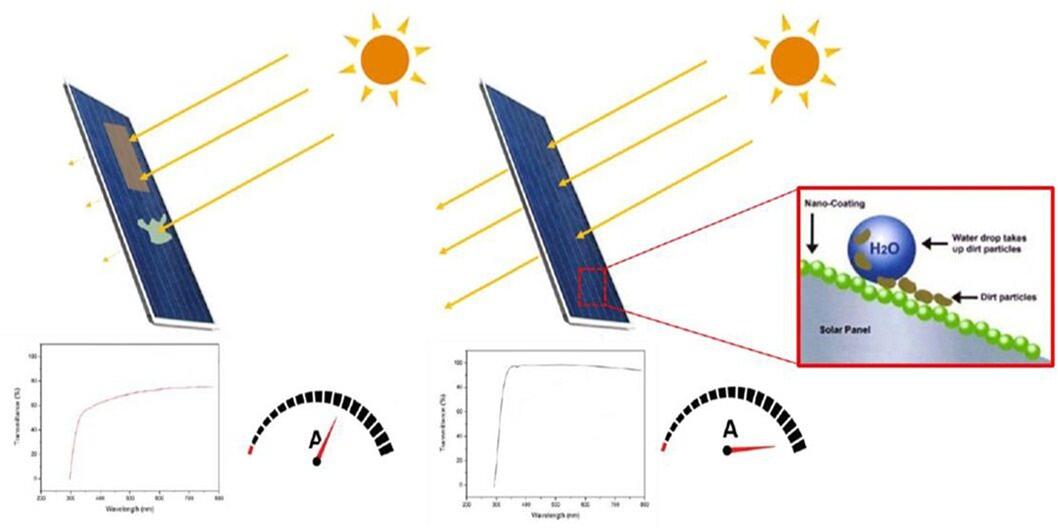

SMA components are developed to be used in devices that convert mechanical vibrations or thermal gradients into electrical energy, or into thermal management systems, where the ability of SMAs to change shape in response to temperature variations is used to control or optimize heat flow in energy systems. Also AM-fabricated SMA actuators or valves are used to control flow, pressure, or other parameters.