METALLURGY

Metallic Melts & Joining

Metals are generally considered as solid materials, but they are at liquid state in several processes and applications such as brazing, soldering, welding, casting, crystal growth, MMC fabrication by infiltration, liquid phase sintering, etc.

In ICMATE, in order to increase the performance and to optimize process fabrications, the behaviour of several metallic systems are studied at solid and liquid state.

ACTIVITIES:

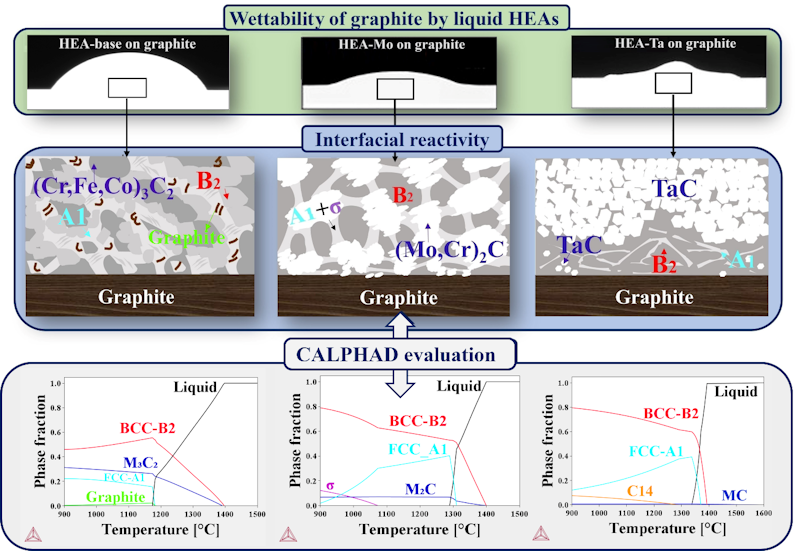

- Studies of wettability of molten metals and design of metal-ceramic interfaces for high temperature applications.

- Joining of materials by liquid-based processes; design and testing of brazing and soldering alloys

- Liquid metal-ceramic interactions in casting processes; identification of suitable mould materials for foundry industries

- Metal phases for enhancing CMC joining and densification.

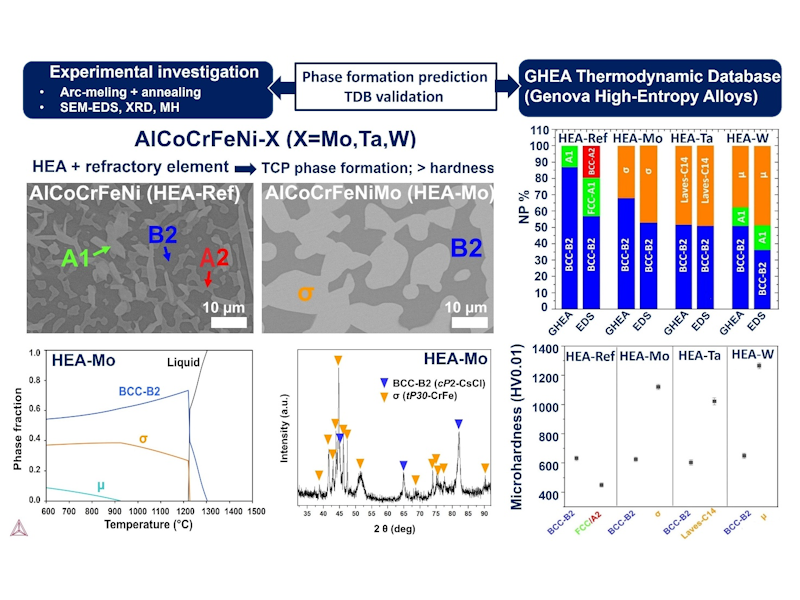

- Multicomponent alloys and steels as structural materials.

- Thermodynamic modeling of metal-ceramic interfaces by CALPHAD

- Coating based on metal systems

- Solidification processes for metallic glasses and high entropy alloys

- Laser welding / laser cutting of metallic alloys: study of processability, microstructural evolution and mechanical behaviour