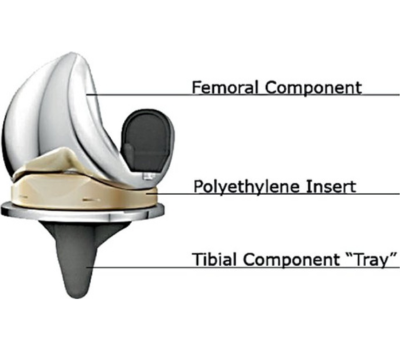

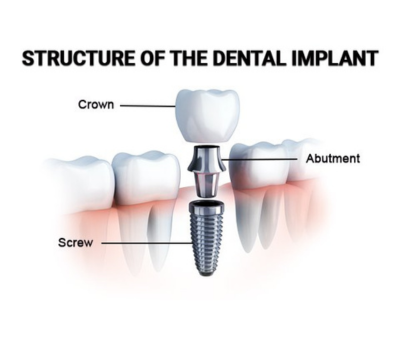

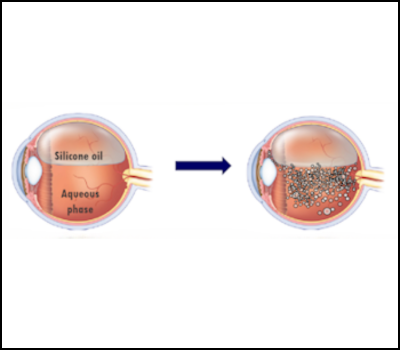

Population aging increases the prevalence of age-related conditions, such as neurodegenerative diseases and the need for prosthetics. To address these issues, surface engineering and interface miniaturization play a major role in improving material performance and implantability of medical devices. Techniques such as spray pyrolysis, spin and deep-coating, chemical vapor deposition (CVD) and plasma-chemical treatments are used to achieve these goals. CVD methods (MOCVD, PECVD, ALD) deposit high-quality films on complex surface geometry at low temperatures and costs, with customizable characteristics. Plasma treatments, such as nitriding, allow for reduced temperatures and times, making them suitable for thermally sensitive materials. ICMATE has successfully used these techniques to develop titanium dental implants, neural devices and metal alloys for prosthetics. Furthermore, the tribochemical and mechanical characterization of surface applied to biocompatible materials in simulated biological environment is widely developed in the ICMATE laboratories.